Typical Applications

When 4"-24" AMERICAN Flex-Lok Ball Joint Pipe is prepared for shipment to the job site, the locking gland is secured against the ball by steel straps. These straps must be removed to free the gland for assembly.

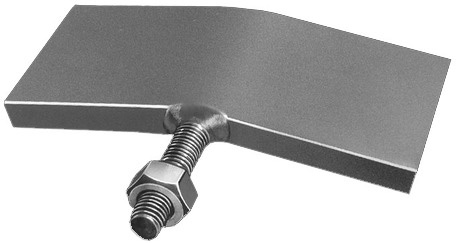

A steel wedge with a welded-on threaded stud, as shown above, is provided for each 4"-24" AMERICAN Flex-Lok joint. One wedge is placed into the space between two lugs and bolted into position. This wedge provides a positive lock to prevent gland rotation after assembly.

River Crossings

- deep water and strong currents

- unstable channels

- potential for flood stage conditions

- where deep trenches, steep banks and other difficult approaches require special construction

Busy Waterways

- where installation time and maneuverability are the critical factors

Tidal Waters

- changing currents and changing water depths

- where the line is subject to movement

River Intakes

- where it is necessary to have a flexible intake, the level of which may be adjusted with changing water levels

Swamps and Floodlands

- where water and earth are subject to seasonal variations

- where the underground line must give with the subsurface movements caused by temperature change, moisture content or other factors

Hillsides

- where steep grades are encountered and where trenching and backfilling are impossible

- where the line may have unstable bedding

Seismic Environments

- where significant ground movements due to earthquakes are anticipated, particularly for piping outside structures where differential settlement can occur

Difficult and Inaccessible Locations

- where trenching and trenchless installation are both impossible

- hazardous working conditions

- where service cannot be interrupted

- where lines are inaccessible for maintenance or repair

- wherever the combination of significant joint deflection and positive joint restraint is required